Archive

Stress Corrosion Testing Performed At Environment Associates in Chatsworth California

Environment Associates can perform various types of accelerated aging and corrosion testing at our two Southern California test Facilities. These tests range from SALT FOG and SALT SPRAY, to STRESS CORROSION and ALTERNATE IMMERSION. We regularly test to specifications such as:

SAE J1455

ASTM B117

MIL-STD-810

MIL-STD-202

RTCA DO-160

NASM 1312-9

MIL-STD-1312-9

And Many More!

Please give us a call today at 818-709-0568, we are happy to assist you on your up and coming test requirements. You can also visit our website at http://www.eatest.com for more information!

Medical Device Testing Lab at Environment Associates, Los Angeles, Ventura County, Santa Barbara, Orange County California

Today’s medical equipment is more portable and found in more locations than ever before, such as in emergency vehicles, aircraft and transported by hand. Therefore, medical equipment must go through the same test regimen as any other product for performance and reliability. Tests include: temperature, humidity, vibration, shock, thermal cycling, ISTA package testing and more. At Environment Associates, we offer the utmost care in providing the right tests and resources for your medical devices. With the range of equipment available, we can test from the smallest implantable device to large diagnostic systems. If needed, we can provide various sizes of anthropomorphic test devices (crash dummies) to simulate actual human body positioning and weight for large medical device testing, such as gurneys, boards, straps, that must be tested under real load conditions.

We can supply the appropriate input voltages to support any performance tests, for any use, from commercial to military. EA can provide fixturing, data acquisition and program management for any large test projects.

Some medical manufacturers may require long-term, multiple-year environmental conditioning to ensure that their product performs throughout its expected life. EA has the equipment and the expertise and is currently running extended-life profiles to ensure the integrity of products required to meet health and safety standards.

Thermal Vacuum Testing Lab in Southern California at Environment Associates

When you want to test your product for extreme space conditions, that include temperatures from 155°C to -175°C at space vacuum altitudes, Environment Associates is your solution. Using this test to determine the unique failures of space mechanisms that orbit the earth is “key” in improving system reliability. Thermal vacuum testing is similar to thermal cycling but adds deep space vacuums for detecting corona/arcing and intermittence and increases a product’s out-gassing. The key failure modes found during this test are: 1) Electrical Intermittence, 2) Thermal Control Issues, 3) Arcing, 4) Corona, 5) Material Out-gassing, and more, to determine a product’s flight-worthiness for workmanship and processing issues.

We provide heating and cooling by direct contact through the use of a conductive chilling plate or the chamber’s shroud surface.

We regularly meet the requirements of contractors such as Lockheed Martin, Boeing, NASA JPL, Northrop Grumman and Astrium.

Contact us to review your particular testing needs. http://www.eatest.com

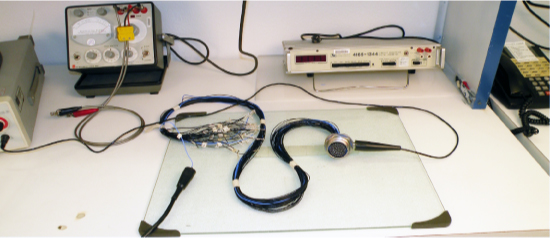

Connector Testing Lab in Ventura County, Santa Barbara, Los Angeles, Orange County, Southern California

http://www.eatest.com your ITAR APPROVED Military Connector Testing Specialists!

If your product uses a connector or terminal, it can be susceptible to a unique set of failures that warrant specific testing conditions to determine the robustness of your design.

The first step in validating your product is ensuring that your connector or terminal is in compliance to its design specification in both structure and assembly. Finding defects, from poor solder joints to bad crimping, is “key” to ensuring that your product terminations are robust. To determine if your connector is manufactured and assembled properly, we provide the following testing services:

• Axial Concentricity

• Maintenance Aging

• Contact Engaging/Separation Force

• Contact Insertion and Removal Force

• Cable Pullout

• Contact Tensile Strength

• Insert Retention

• Mating/Un-mating Force

• Durability

• Contact Retention

• Resistance to Probe Damage

• Crimp Tensile Strength

• Coupling Torque

• External Bending Moment

• Coupling Pin Strength

• Gauge Location

• Gauge Retention

• Accessory Thread Strength

• Pin Contact Stability

• Solderability

Even after a connector is properly inspected for its mechanical properties, electrical performance must be measured to ensure that impurities, contaminates or process hasn’t affected the life of the product. That is why we provide the following tests for connectors or terminals:

• Contact Resistance

• Low-Level Contact Resistance

• Insulation Resistance

• Dielectric Withstanding Voltage

• Shell-to-Shell Conductivity

• Discontinuity Monitoring

Our qualified, technical staff can prepare samples that include the assembly of the test articles, validating the pin-outs of the connector and breadboard, and the manufacturing of test leads to measure voltage drops across the connectors. For large tests, we can mount the test leads to data-acquisition terminals and set up software programs to measure all testing parameters.

The application of your connector can cause different effects to your product and to those items that communicate with your product. Environment Associates provides a number of tests to evaluate the service life of your product to your connector and terminal. These tests are as follows:

· Drop Test

· Vibration Durability while Monitoring Discontinuity

· Water Immersion

· Power Wash Testing

· Air Leakage

· Magnetic Permeability

· HALT – HASS – Accelerated Testing

· Solar Radiation

· Salt Fog

· Blowing Dust

· Temperature/Humidity – Vibration – Life Cycle Testing

· Dry Circuit Testing – Current Cyclic Testing

· Micro-Fretting

· Corrosion Testing

We are approved by the DSCC (Defense Supply Center Columbus) for testing MIL-DTL-38999 Connectors and are Registered by the US State Department to Handle ITAR designated programs!

Vibration Testing Lab near Ventura County California

http://www.eatest.com As specialists in dynamic testing, we provide equipment capable of exerting a 6,000 to 18,000 pound force with the capacity to perform closed-loop control from a single input to multiple channel inputs (from 2 to 32) with averaging or notched channel control. Vibration control systems can be programmed for real time monitoring, scheduled for length of time, or level scaled by dB or percentage, or scaled at various durations at different acceleration levels.

We have electro-dynamic shakers at 2-inch stroke and servo-dynamic shakers at 4-inch stroke with a range of capabilities. Most of our electro-dynamic shakers are attached with slip-plates to perform multi-axis testing.

We regularly perform vibration testing to MIL-STD-810, RTCA DO-160, MIL-STD-750, MIL-STD-202, as well as ISTA, EN, IEC, and ASTM specifications. We also provide unique tests like Gunfire, Transportation Packaging and NAVMAT screening. .

When called upon, we provide specialized environments that include Temperature, Humidity, Rapid Temperature Change, Salt Spray and Combination Environments with our vibration tests that can be supervised 24/7 with on-site monitoring or remote monitoring.

The key to developing a great test plan is having vibration fixtures that are non-resonance, controllable configurations, manufactured from aluminum or magnesium materials that hold single or multiple parts for test. Many times, we stock pre-configured expansion heads and plates that can be easily incorporated to your test article, which will lower your fixture cost and accelerate your time to test. Each fixture is tested for performance and tuned to perform at its best. Let us help with your fixture designs and manufacturing needs.

Real-time performance assessment (Vehicle or Machine Vibration Data) can be provided by our systems technicians by instrumenting your product with accelerometers, thermal couples, stress and strain devices, measurements on test tracks, or machinery for improved testing in the lab. As an engineer, you need to know what you are designing for and the conditions for use so you don’t under or over test your product. Having this information is also important for your FEA design staff to determine stress input.